Process

High-purity, High-quality rare earth products

by Shin-Etsu advanced technologies.

High level technology is required for the separation and purification of rare earths.

Shin-Etsu Chemical started researching rare earths in 1961 and soon after we started using the solvent extraction method (*1) for separation and purification of rare earths.

Color televisions were widely used in the 1960s, and rare earths were used for these televisions. This was the first foundation of Shin-Etsu Chemical’s current rare earths business. In 1971, we launched a pilot plant for mass production, and we continue to operate a solvent extraction system in Japan today.

※1 Solvent extraction method: By mixing and contacting a rare earth solution and an organic solvent (not soluble in water), separation is performed using the difference in distribution between the aqueous phase and the organic phase that is slightly different for each rare earth element.

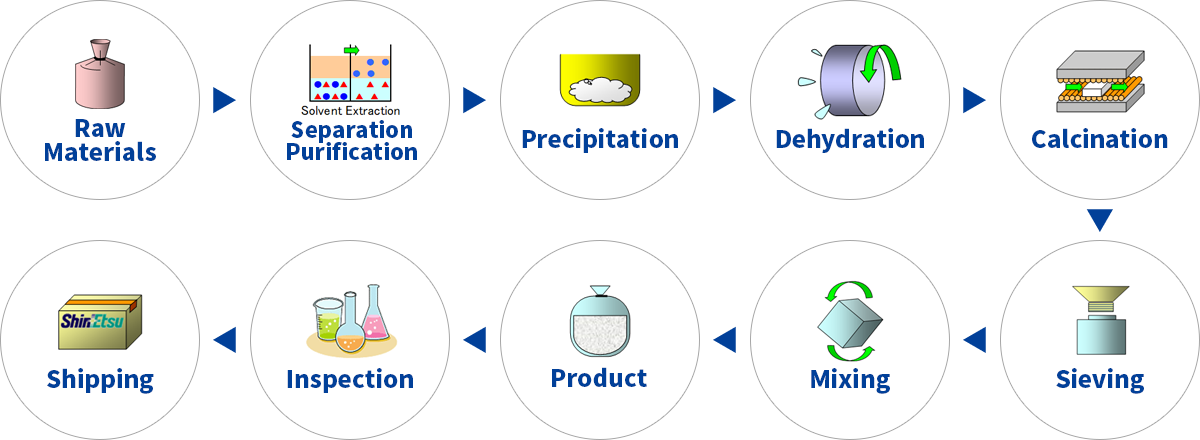

Manufacturing Process of Shin-Etsu Rare Earth Oxides

We have various types of analysis apparatus.

We continue to provide reliable quality to all customers.